Raptor’s Evolutionary Path: A Case Study in First-Principles Engineering

SpaceX’s Raptor engine has undergone a series of iterations, augmentations, and deletions throughout its development, following Elon Musk’s first-principle approach. The evolution of this engine represents one of the most fascinating case studies in modern aerospace engineering—a testament to SpaceX’s relentless optimization methodology.

What makes the Raptor engine particularly intriguing from an engineering perspective is how it embodies the iterative optimization process. Unlike traditional aerospace development cycles where changes tend to be incremental and conservative, SpaceX has pushed the boundaries of what’s possible through aggressive iteration cycles.

Iterations: From Prototype to Current Architecture

1. Prototype to Version 1 (Raptor 1)

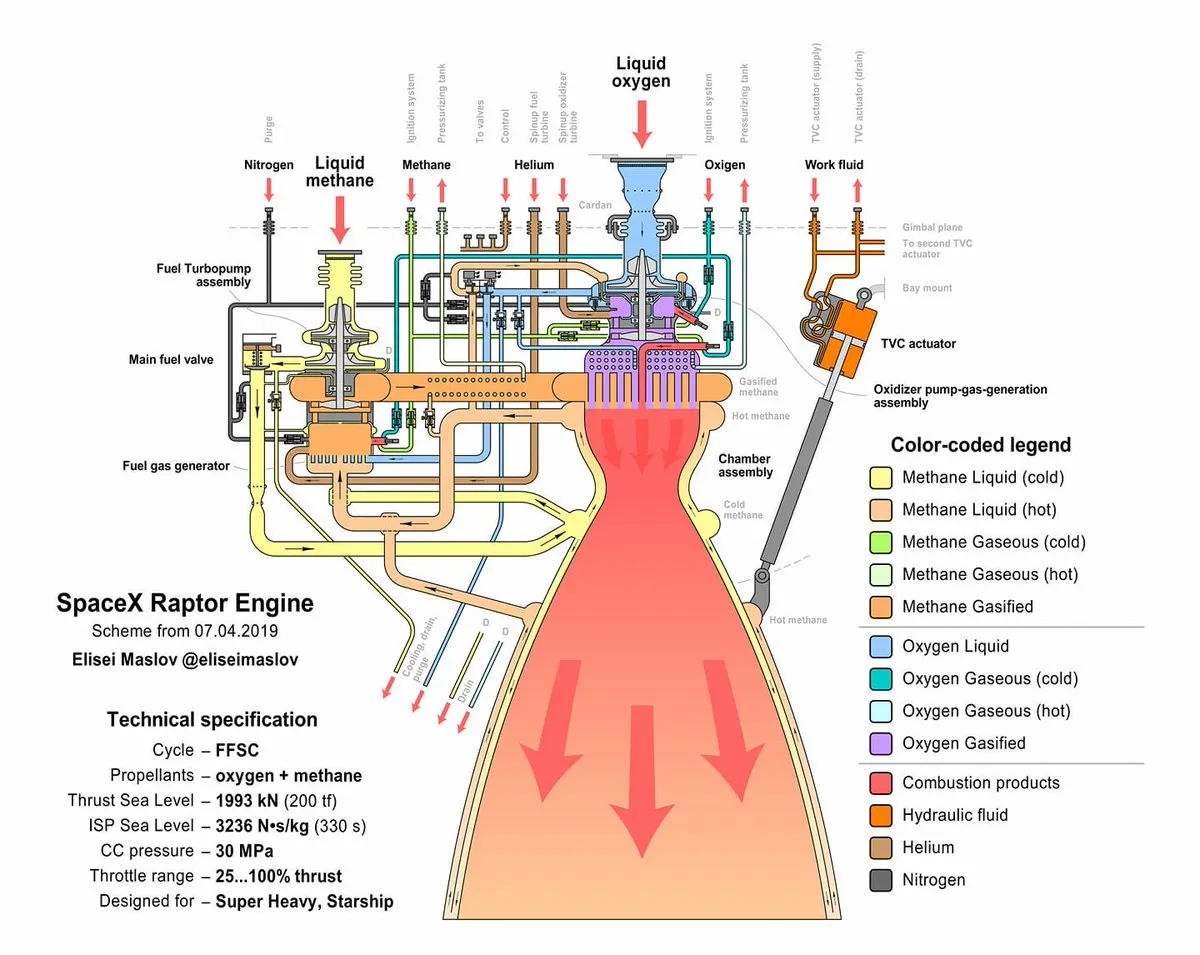

The initial prototype engines, tested at SpaceX’s McGregor, Texas facility, focused on validating the full-flow staged combustion cycle—a thermodynamic cycle previously deemed too complex for practical implementation. This cycle represents an O(n) improvement in efficiency over the more commonly used gas generator cycles.

The mathematical advantage is straightforward: in a full-flow staged combustion cycle, all propellant mass flows through the main combustion chamber, whereas gas generator cycles waste a portion of propellant to drive turbopumps. This results in a higher specific impulse (I_sp), the key efficiency metric for rocket engines.

2. Version 1 to Version 2 (Raptor 2)

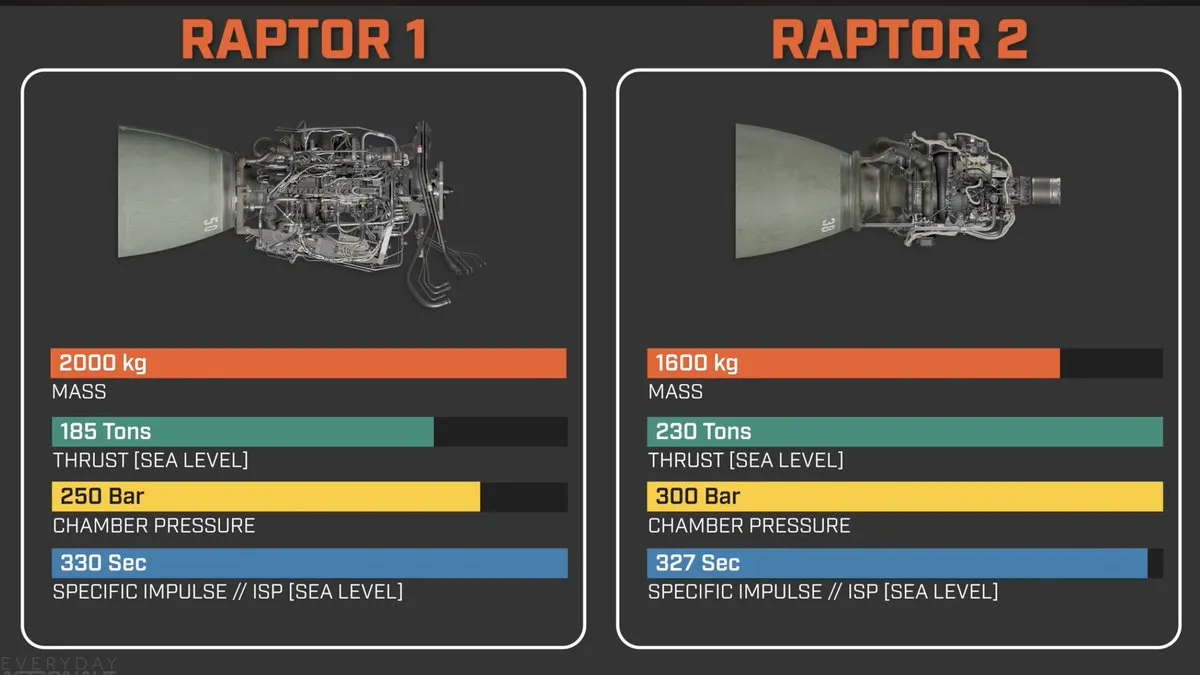

The transition from Raptor 1 to Raptor 2 demonstrates SpaceX’s commitment to both performance enhancement and, crucially, manufacturability:

- Material Science Advancements: Implementation of high-temperature alloys in the turbopump and combustion chamber, enabling higher chamber pressures (from ~270 bar to ~300 bar)

- Cooling Channel Optimization: Refined cooling channels in the engine bell using computational fluid dynamics to model heat transfer coefficients more precisely

- Thrust Increase: From initial targets of ~1,700 kN to ~2,400 kN for sea-level variants—a ~41% increase with minimal mass penalty

What’s particularly notable here is the simultaneous pursuit of seemingly conflicting objectives: increased performance and reduced manufacturing complexity. Traditional engineering often treats these as trade-offs; SpaceX treated them as simultaneously achievable goals.

3. Version 2 to Current Version

The latest iterations have focused on:

- Manufacturing Streamlining: Elimination of complex machining steps to reduce per-engine cost by approximately 40%

- Turbopump Refinements: Redesigned impellers to mitigate cavitation risks at high rotational speeds (>30,000 RPM)

- Combustion Stability Enhancements: Implementation of acoustic dampening features to prevent destructive resonant vibrations

Augmentations: Pushing Physical Boundaries

1. Thrust Augmentation

The continual thrust increases in Raptor represent more than simply “turning up the power”—they require addressing cascading engineering challenges:

- Higher thrust demands higher propellant mass flow, which necessitates more powerful turbopumps

- More powerful turbopumps require more robust bearings and seals to handle increased mechanical stresses

- Higher chamber pressures create exponentially greater thermal loads on combustion chamber walls

The elegant solution has been to increase the chamber pressure to approximately 300 bar—significantly higher than any operational rocket engine. This allows greater thrust from a compact package, optimizing the thrust-to-weight ratio, a critical parameter for reusable systems.

2. Specific Impulse Improvements

The specific impulse (I_sp) of an engine is effectively its fuel efficiency, mathematically represented as:

I_sp = F / (m_dot * g_0)Where F is thrust, m_dot is propellant mass flow rate, and g_0 is standard gravity.

Raptor’s vacuum variant achieves approximately 380 seconds of specific impulse—near the theoretical maximum for methane/oxygen propellants. This required:

- Optimization of the combustion chamber geometry to ensure complete propellant mixing

- Precise control of oxidizer-to-fuel ratio (O/F) to maximize energy release

- Nozzle extension design optimized for expansion in vacuum conditions

3. Reliability and Reusability

Perhaps the most underappreciated augmentation has been the enhancement of operational robustness:

- Implementation of health monitoring systems capable of detecting anomalies before they become failures

- Margin increases in critical components to withstand the stresses of repeated use

- Design changes to facilitate rapid inspection and component replacement

Deletions: The Underappreciated Art of Simplification

1. Simplification of Design

The engineering discipline of knowing what to remove is often more challenging than knowing what to add. SpaceX has mastered this through:

- Elimination of unnecessarily complex valves and control systems

- Consolidation of structural elements to reduce part count

- Removal of diagnostic sensors once enough data was collected to validate models

This resembles the process of regularization in machine learning—deliberately simplifying a model to improve its generalization capabilities.

2. Weight Reduction

Mass is the eternal enemy of rocket engineering. Every gram saved in engine mass translates to potential payload capacity. The Raptor team has achieved significant mass reductions through:

- Topology optimization of structural components, removing material where stresses are minimal

- Replacement of conventional manufacturing techniques with advanced methods like 3D printing of complex components

- Integration of functions into single components rather than assemblies of multiple parts

The Mathematical Beauty of Engine Development

What fascinates me most about Raptor’s development is how it represents a multidimensional optimization problem. The engine’s performance characteristics can be modeled as a vector in a high-dimensional space, where each dimension represents a parameter like thrust, specific impulse, weight, reliability, and cost.

SpaceX’s approach has been to navigate this complex parameter space not through small, cautious steps, but through bold jumps followed by rapid testing and refinement. This methodology aligns perfectly with global optimization techniques like simulated annealing, where the search space is explored aggressively early on, then refined with more precise local optimization.

Conclusion: Lessons Beyond Aerospace

The evolution of the Raptor engine offers lessons that extend beyond rocket science:

-

Iterative development yields non-linear improvements: Each Raptor iteration didn’t just incrementally improve—it often achieved step-changes in performance.

-

Simplification can be more powerful than addition: The courage to remove complexity often yielded the greatest gains.

-

Manufacturing is as important as performance: The best design is worthless if it can’t be built efficiently.

-

First principles trump historical precedent: By questioning fundamental assumptions, SpaceX achieved what was previously considered impossible.

For engineers and entrepreneurs alike, Raptor’s development trajectory serves as a masterclass in innovation methodology—one that balances theoretical ideals with practical constraints while never accepting that the current state is the best possible outcome.

As SpaceX continues to refine this remarkable engine, we’re witnessing not just the evolution of propulsion technology, but a template for how to approach complex engineering challenges across any domain.

Last updated on May 14, 2025 at 12:17 AM UTC+7.